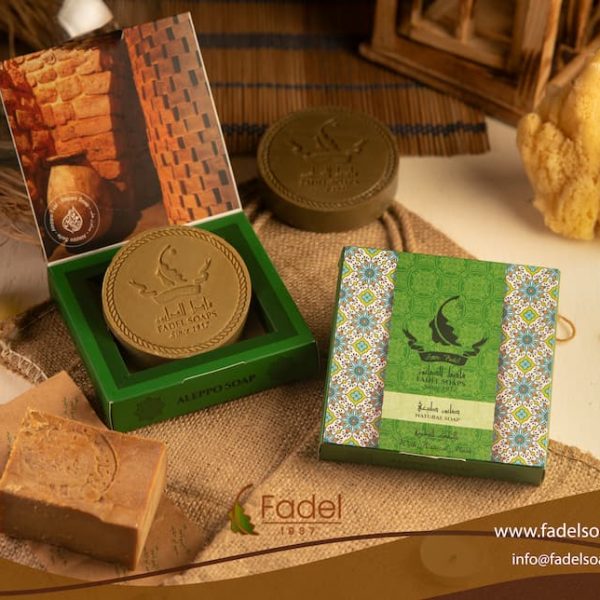

Fadel Soap Company

Quality is our goal, your trust is important to us, and our name is our address. Al-Fadel Company for the manufacture of laurel soap from olive oil offers you natural Syrian laurel oil soap, the most natural types of laurel soap.

long experience

We grow generation after generation

Global Quality

How to make Original laurel soap

The process of making laurel soap goes through several stages, which are as follows:

The first stage:

1- Pour water and original olive oil in successive quantities, add sodium hydroxide and mix with them the original bay leaf oil. Cook and stir until it reaches a suitable temperature.

At this stage, the olive oil produced from the second pressing is used, not the first pressing, which is used for cooking or eating.

The second stage:

2- At this stage, the laurel soap is poured in liquid form on the ground and left for about 6 to 8 hours to solidify. Fenugreek seeds can be added to these ingredients.

Stage 3:

3- At this stage, the soap is cut after it has solidified in a primitive way and sealed with special tools bearing the brand of our company, Al Fadhel Company for the Manufacture of Original Laurel Soap.

Stage Four:

4- At this stage, the soap is stored and arranged in a compact manner, leaving spaces for air passages between them.

After 6 months, the soap will have dried in the open air and lost 95 percent of its moisture. It will then be packaged and sold to the consumer.

The more the laurel soap dries and gets rid of its moisture, the better its quality and the better its smell.

Original laurel soap benefits and its uses

- Gives softness and shine

- Moisturizes face and body

- Used for bathing and cleaning

- Non-irritating to the skin

- It smells fragrant and refreshing.

- Kills germs and bacteria

- Getting rid of acne on the face

- Helps soften the skin

Distinctive products made from pure natural materials

A wide range of products Original laurel soap

80+

year

expertise

An industry passed down through generations